What is TIG Welding?

Transcript:

What is TIG welding?

Tig stands for Tungsten-inert gas welding. The American welding society calls this process “Gas Tungsten Arc Welding” or GTAW. You might also hear it called “heliarc welding.”

Tig welding uses a tungsten electrode. Now, tungsten has an extremely high melting point. When you tig weld, the electrode gets hot but it doesn’t melt. We say it is a non-consumable electrode. That doesn’t’ mean it lasts forever, just that it doesn’t melt and become part of the weld.

You see, in lots of other welding processes, the electrode melts and become filler metal. Those are consumable electrode processes.

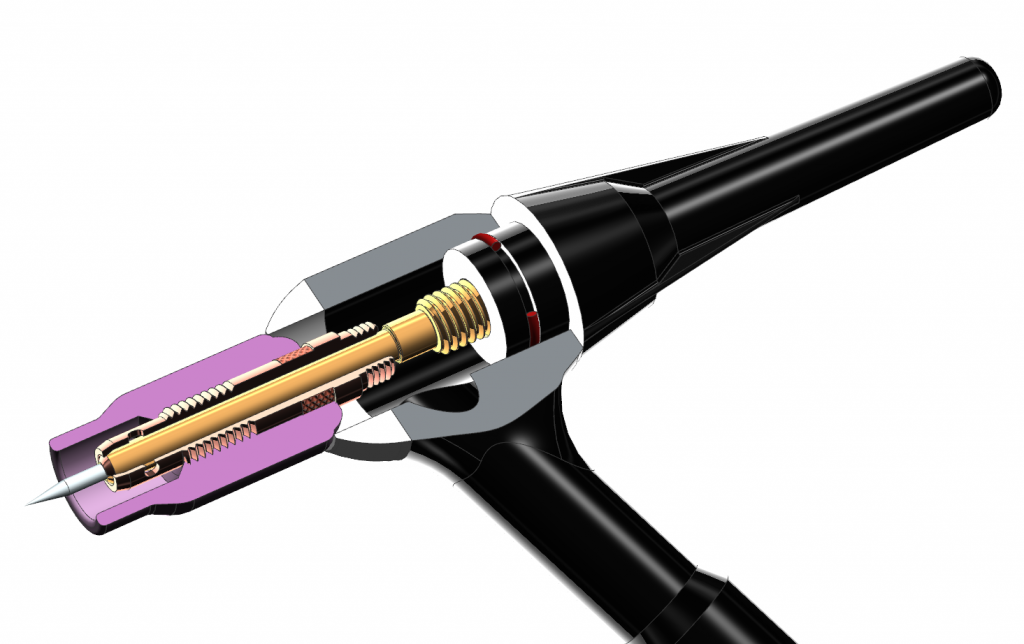

So here is the tungsten electrode being held in a TIG torch. The electrode slips into a collet, and the collet tightens up against the collet body. You can adjust the length the electrode sticks out of the holder by loosening up the end cap. When you tighten the end cap, the collet clamps down on the electrode.

Tig works by melting the base metal (that is, the metal that makes up the two pieces that are to be joined. The heat is generated by an electric arc that forms between the base metal and the tungsten electrode. You can control the amount of heat with a foot pedal or with a thumbwheel on the torch.

For most metals, the current is Direct Current or DC. DC is like the current flowing from a car battery. One wire is always the negative and one is always the positive. In DC TIG welding, the electrode is usually negative, and the workpiece is positive. The term DCEN is used, indicating that the current is DC, and the electrode is negative. This is also called “straight polarity,” but DCEN is a more descriptive term. DCEN puts most of the heat on the workpiece, and it is the most common setup.

When welding aluminum, however, AC is used. In AC, the positive and negative voltages switch back and forth between the electrode and the workpiece. This puts more heat on the electrode, but it has a cleaning effect on the workpiece. You see aluminum forms oxides that float to the top of the weld and prevent a good weld. The backwards flow of electricity during half the cycle helps control these oxides.

In an electric circuit the current flows in a loop. In TIG welding, the current has to flow in a complete circle from the machine, to the torch, into the work, and back to the machine. A work lead is clamped to the work to complete the circuit from the workpiece back to the machine.

Now, you can TIG weld with or without filler metal. That’s not a choice in a lot of other processes. If you want to add filler metal to a TIG weld, you use filler rod, which is just a rod of metal with a specific alloy. You want to be sure the filler metal you are using is compatible with the base metal and has the strength required for the job.

The molten metal is protected by a shielding gas. This gas, usually argon and sometimes helium or other gases, keeps the molten metal from reacting with oxygen and water vapor in the atmosphere. The shielding gas is stored in high pressure cylinders like these. The pressure is reduced to a usable level by a device called a “regulator.”

So in summary, TIG Welding is an electric arc welding process. It uses a nonconsumable tungsten electrode. Filler metal is added separately, and the shielding gas comes from a high pressure cylinder.

I like the way you describe it, please add other welding processes, like PAW, EBW, LBW, most videos they don’t explain them well.

Hey Bob,

I’ve just returned to the classroom after 5 years in aerospace to learn welding processes and hopefully add another string to my bow. I happened across your YouTube channel today and found your videos very insightful and helpful in explaining the difference between all the welding processes and the such. I would love to see more videos from you and I’m sure I speak for many when I say that.

a newbie welder

pretty cool and easy for us to understand the core information