What is MIG Welding?

Transcript:

What is MIG welding?

Mig stands for Metal inert gas welding. The American welding society calls this process “Gas Metal Arc Welding” or GMAW. You might also hear it called “wire welding.”

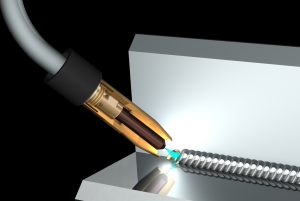

In Mig welding a thin wire acts as the electrode. This wire is fed from a spool mounted on or inside the welding machine through a flexible tube and out of the nozzle on the welding gun or torch. The wire is fed continuously when the trigger on the welding gun is pulled. When the trigger is pulled, it also switches on the welding current and a “shielding gas.”

An electric arc forms between this wire electrode and the workpiece and heats both metals above their melting point. These metals mix together or “coalesce” and solidify to join the workpieces together (or into a single piece). The metal in the parts to be joined is called the “base metal” and the metal that comes from the melting wire electrode is called “filler metal.” Because the wire electrode melts as it is being used, the MIG wire is a “consumable electrode.” MIG welding always adds filler metal to the joint.

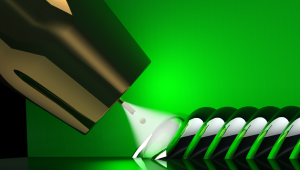

Here is the MIG wire being fed through the wire feeder into the flexible tube or “conduit liner” The liner goes through the hose or “welding lead” all the way to the torch nozzle. At the nozzle, the wire is fed through a “contact tip” and comes out at the point of the weld.

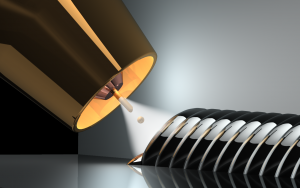

Shielding gas is also fed through the welding lead. It goes a through a gas diffuser and flows out through the nozzle. This shielding gas, which is often a mix of Argon and CO2 protects the molten metal from reacting with oxygen, water vapor, and other things in the atmosphere.

The shielding gas is stored in high pressure cylinders like these. The pressure is reduced to a usable level by a device called a “regulator.”

In MIG welding, all of the machine controls are set on the machine itself. The most important of these are polarity, wire speed and voltage. The trigger on the gun is just and on/off switch. For most MIG welding, the current is Direct Current or DC. DC is like the current flowing from a car battery. One wire is always the negative and one is always the positive. In DC MIG welding, the electrode is usually positive, and the workpiece is negative. The term DCEP is used, indicating that the current is DC, and the electrode is positive. This is also called “reverse polarity,” but DCEP is a more descriptive term.

In an electric circuit the current flows in a loop. In MIG welding, the current has to flow in a complete circle from the machine, to the torch, into the work, and back to the machine. A work lead is clamped to the work to complete the circuit from the workpiece back to the machine.

So in summary,MIG Welding is an electric arc welding process. It uses a consumable wire electrode. Filler metal is added automatically, and the shielding gas comes from a high pressure cylinder.

Excillent but explain in telugu

Try to explain in telugu

Someone use your videos:

https://youtu.be/4J0VRWL_7gw?t=5